There are many ways to learn about 3D printing, but a great place to start is by reading one of the many excellent books on the subject.

3D printing is an additive manufacturing technology that creates three-dimensional objects by successively depositing material until the desired shape is built up. Unlike traditional manufacturing methods, 3D printing offers a versatile and rapid way to produce objects of virtually any shape from a digital file.

Although 3D printing technology has been around for decades, it has only recently become widely available and affordable for consumers and small businesses. As a result, there is a growing need for information on how to use 3D printers and design 3D-printable objects.

There are a number of ways to learn about 3D printing. One option is to take an online course or watch a tutorial video. Many online courses are available for free, and there are also a number of paid courses that offer more in-depth instruction.

Another way to learn about 3D printing is to attend a workshop or meetup. These events are typically organized by local makerspaces or 3D printing companies, and they offer a great opportunity to learn about the technology and meet other people interested in 3D printing.

Finally, another option for learning about 3D printing is to simply start experimenting with a 3D printer. There are a number of free online resources that offer 3D models that can be downloaded and printed. experimentation is often the best way to learn, and there is no shortage of resources available to help you get started.

What Is 3D Printing?

3D printing is a process of making three-dimensional solid objects from a digital file.

3D printing is a process of making a three-dimensional object from a digital file. It is also known as additive manufacturing. 3D printing is done using a printer that deposits materials layer by layer to create the desired object.

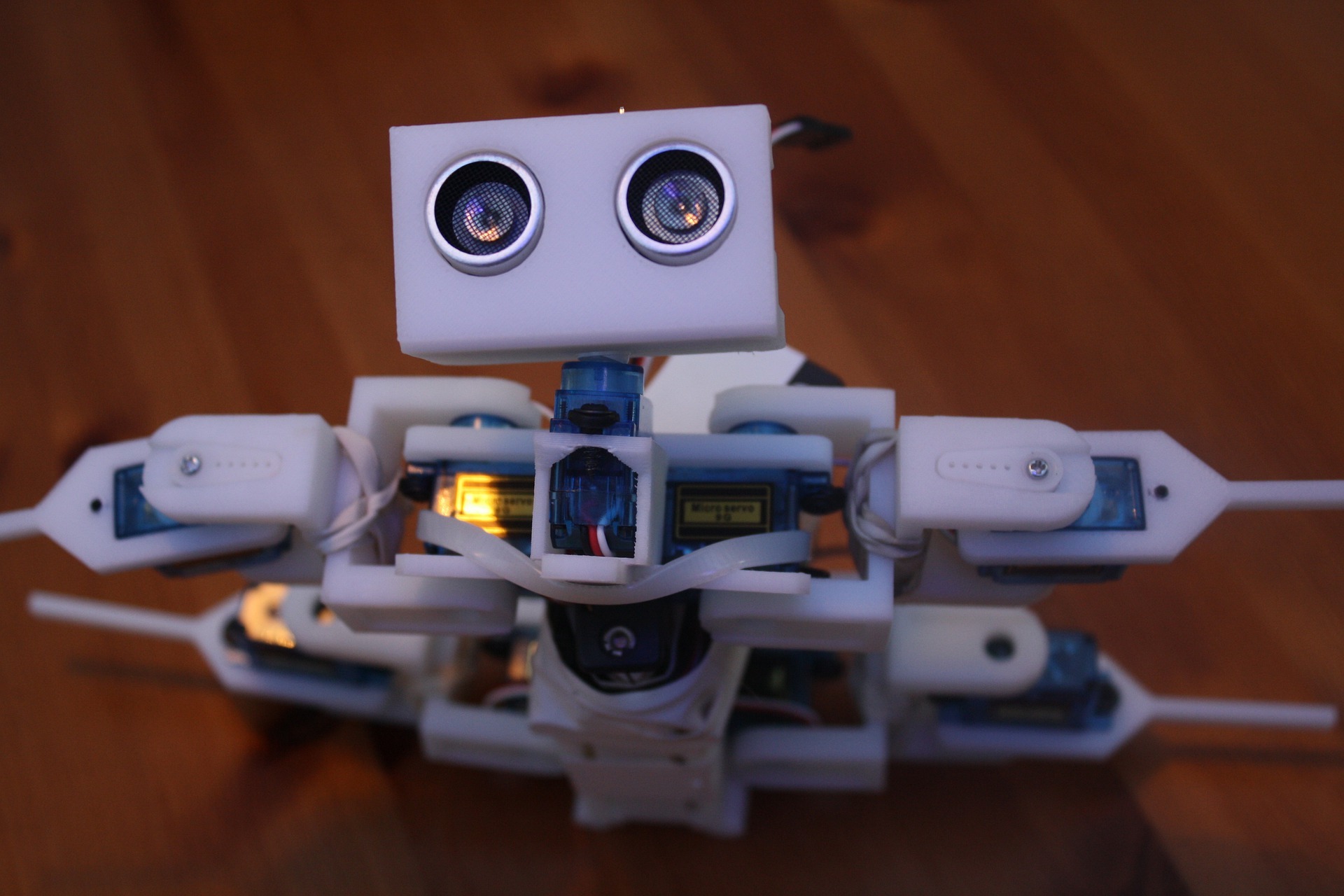

3D printing has revolutionized manufacturing and prototyping. It has made it possible to create objects that were previously impossible to make. 3D printing is used in a variety of industries, including aerospace, architecture, automotive, biomedical, and dental.

3D printing is not just for prototyping. It can also be used to create functional objects. For example, 3D-printed prosthetics are becoming increasingly popular. They are cheaper and more comfortable than traditional prosthetics.

3D printing is changing the way we think about manufacturing. It is making it possible to create complex objects quickly and cheaply. If you are interested in learning more about 3D printing, there are a variety of resources available online.

How Does 3D Printing Work?

Three-dimensional printing is a process of making a three-dimensional object from a computer model.

3D printing technology has come a long way in recent years, and it shows no signs of slowing down. If you’re not familiar with 3D printing, it’s basically a process of making three-dimensional solid objects from a digital file. The printer reads the file and creates a three-dimensional model by layering thin sheets of material on top of each other.

3D printing is used in a variety of industries, from medical to aerospace. It’s also becoming more popular for hobbyists and DIYers who want to create their own three-dimensional objects.

If you’re curious about how 3D printing works, read on for a step-by-step explanation.

1. The first step is to create a digital file of the object you want to print. This can be done using computer-aided design (CAD) software or by scanning an existing object.

2. Once you have your file, it’s time to prepare it for printing. This step is called slicing, and it involves breaking the file down into thin layers that the printer can understand.

3. Next, you’ll need to choose a material for your print. There are a variety of filaments available, each with its own properties.

4. Once you’ve selected a material, it’s time to load it into the printer. Most 3D printers have a spool of filament that feeds into the machine.

5. Now you’re ready to start printing! The printer will take your file and start creating the object layer by layer.

6. Once the print is finished, you’ll need to remove it from the printer and allow it to cool.

And that’s it! That’s the basic process of 3D printing.

As you can see, it’s a fairly simple process. But don’t be fooled—3D printing is capable of creating some amazing objects.

What Are The Benefits Of 3D Printing?

3D printing can create objects of any shape or size, making it possible to create objects that cannot be created using traditional manufacturing methods.

3D printing technology has come a long way in recent years, and its applications are growing in both the consumer and industrial spheres. Here are just a few of the benefits of 3D printing:

1. Increased accuracy: With 3D printing, there is no margin for error when it comes to manufacturing parts or products. Every detail can be replicated with precision, ensuring that your final product is exactly as you intended it to be.

2. Increased speed: Traditional manufacturing methods can be quite time-consuming, but 3D printing can drastically cut down on production time. In some cases, it’s even possible to produce a product on-demand, without having to wait for batch production cycles.

3. Cost savings: Because of its increased accuracy and speed, 3D printing can save you money in the long run. In addition, the technology is becoming more and more affordable, making it a viable option for small businesses and individual consumers alike.

4. Increased flexibility: With 3D printing, you’re not limited to standard shapes and sizes. Complex geometries and custom designs are now within reach, giving you the freedom to create products that are truly unique.

5. Environmental friendliness: 3D printing is a much more environmentally-friendly manufacturing process than traditional methods. It produces less waste, and the energy required to operate a 3D printer is often lower than that of traditional manufacturing equipment.

These are just a few of the many benefits of 3D printing technology. As the technology continues to evolve, we can only imagine what new and exciting applications will be made possible.

What Are The Limitations Of 3D Printing?

The limitations of 3D printing are that it is slow, expensive, and has a limited material selection.

3D printing technology has revolutionized manufacturing and prototyping, but it still has limitations. One of the biggest limitations is the range of materials that can be used. 3D printers can only use materials that are in a powder or liquid form. This limits the types of products that can be created with 3D printing.

Another limitation of 3D printing is the accuracy of the printed product. 3D printers can create products with very fine detail, but they are not yet able to create products with the same level of detail as traditional manufacturing methods.

Finally, 3D printing is a slow process. It can take hours or even days to print a large product. This limitation is slowly being overcome as faster 3D printers are developed.

Despite these limitations, 3D printing is an exciting and rapidly evolving technology with a wide range of potential applications.

How Much Does A 3D Printer Cost?

A 3D printer typically costs around $200.

3D printers have come a long way since they were first introduced in the 1980s. Today, they are smaller, more affordable, and easier to use than ever before. So, how much does a 3D printer cost?

The answer to this question depends on a few factors, such as the type of printer, the quality of the printer, and the features you need. For example, a basic 3D printer that only prints in one color may cost around $200, while a more advanced printer that can print in multiple colors and has a larger build volume may cost $500 or more.

If you are looking for a 3D printer for your home or small business, you may be able to find a good quality printer for under $1000. However, if you need a high-end printer for industrial use, you could be looking at a price tag of $5000 or more.

Of course, the cost of a 3D printer is not just the purchase price of the machine. You will also need to factor in the cost of the filament (the plastic used to make the 3D prints), which can range from $20 to $100 per kilogram. Additionally, you may need to pay for shipping and handling if you purchase your printer online.

To summarize, the cost of a 3D printer depends on a number of factors, including the type of printer, the quality of the printer, the features you need, and the cost of the filament. A basic 3D printer may cost around $200, while a more advanced printer could cost $500 or more.

FAQ

How Do I Choose A 3D Printer?

What Software Do I Need For 3D Printing?

What Are The Best Sources For Learning About 3D Printing?

Conclusion

3D printing technology is one of the most popular and widely used technologies in the manufacturing industry today. It allows manufacturers to produce parts and products with greater accuracy and precision than ever before. As a result, 3D printing has become an essential tool for manufacturers around the world. If you’re interested in learning about 3D printing, there are a number of resources available to you. You can find books, online courses, and even software that will help you learn about this fascinating technology.

I hope this answers your question about 3D printing. If you have any further questions, please don’t hesitate to ask in the comments section below.

Author

-

I'm Shahrear, a Designer Lead who loves electronics. Since 2003, I’ve been traveling and living all over the world. I love breaking down complex concepts in electronics and presenting them to others in an approachable way. I think that the language used in most books about electronics is hard for people who don't already know about electronics to understand. I want that to change. So, I've started blog where I talk about everything on electronics for people who are just starting out.

View all posts