We cover stories about 3d printing innovative manufacturing and new concepts.

Advanced Schematic Capture Editor

KiCad is an advanced schematic capture editor. An advanced schematic capture editor is a powerful tool for creating and editing electronic schematics. It offers a wide range of features and options for customizing the look and behavior of the schematic. With an advanced editor, you

What Are the Best Open Source Schematic Capture And PCB Layouts on the Market?

KiCad is an open source schematic capture and pcb layout program. Open source hardware design tools are becoming increasingly popular. This is due in part to the growing popularity of open source hardware, but also because they offer a number of advantages over proprietary tools.

Everything You Need to Know About Free Schematic Capture And PCB Layout Software

KiCad is a free and open source electronics design suite. There are many different software programs that you can use to capture schematics and design printed circuit boards (PCBs). Some are free, while others are not. In this article, we will take a look at

Altium Designer Schematic Capture: Pros and Cons They Don’t Tell You

Altium Designer is a CAD program that allows users to create electronic circuit schematics. Many software programs can be used for schematic capture, but one of the most popular is Altium Designer. This program has a wide range of features that make it ideal for

Mentor Graphics Schematic Capture

Mentor Graphics Schematic Capture is a software program that lets you create digital circuit designs. Mentor Graphics is a world leader in electronic design automation (EDA) software. Their flagship product, PADS, is used by engineers to design and validate the connectivity of electronic components. PADS

Electronic Schematic Capture And Simulation Program

Proteus An electronic schematic capture and simulation program is a software application that allows engineers to design and simulate electronic circuits. These programs are used to test the behavior of electronic components and to verify the accuracy of circuit designs. Schematic capture programs typically provide

Gate Location Injection Molding

The gate is the location where the molten plastic enters the mold cavity. In gate location injection molding, the gate is placed on the side of the mold instead of the center. This allows for shorter cycle times and less material waste. What Is The

Injection Molding Tolerance Chart

Injection molding is a process in which plastic is melted and injected into a mold to create a desired shape. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a wide variety

Injection Molding Tolerances

Injection molding is a process in which molten material is injected into a mold to create a desired shape. Tolerances are the allowable deviations from the specified dimensions of a part. Injection molding is a manufacturing process for producing parts by injecting molten material into

Sink Mark Injection Molding

Sink mark injection molding is a type of injection molding that creates a sunken mark in the molded part. In the early days of plastic injection molding, one of the challenges was getting rid of sink marks. Sink marks are caused by the plastic not

Best Plastic Injection Molding

There is no one “best” plastic injection molding machine – each has its own advantages and disadvantages depending on the application. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a host

Injection Molding Services

Injection molding services provide a quick and easy way to create custom plastic parts. Injection molding services can be very inspirational because they can help people in many different ways. For example, they can help people who are unable to have children of their own

Injection Molding Materials

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding can be performed with a wide variety of materials, including metals,

Injection Molding Processing

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding is a process that was developed in the mid-1800s to create various objects and materials. The process involves injecting a molten material into a mold, which is

3d Printing Vs Injection Molding

Injection molding is more expensive than 3D printing. In 2012, a team of engineers from Michigan Tech set out to create a prosthetic hand using 3D printing technology that would be more affordable and accessible than traditional prosthetics. After months of trial and error, they

Injection Molding Plastic Types

The three main types of plastic used in injection molding are polyethylene (PE), polypropylene (PP), and polystyrene (PS). Injection molding is a process that can be used to create a wide variety of parts and products from a variety of plastics. Injection molding is a

Plastic Injection Molding Materials

The most common plastic injection molding materials are thermoplastics. In the early days of plastic injection molding, materials were limited to just a few types of synthetic polymers. But with the development of new materials and the refinement of existing ones, the potential applications for

Plastic Injection Molding Service | HibeXen

A plastic injection molding service is a company that manufactures plastic products by injection molding. In the early days of plastic injection molding, one company found itself at the forefront of this new technology. This company, which was founded in the early 1900s, was the

Process Of Injection Molding | HiberXen

The process of injection molding is a manufacturing process for producing parts by injecting molten material into a mold. Injection molding is a process that has been around for centuries, dating back to the 15th century. It was originally used to create metal objects, but

Plastic Injection Molding | HiberXen

Injection molding is a process in which plastic is melted and injected into a mold to create a desired shape. In the early days of plastic injection molding, one company in particular was struggling to find success. The company’s founder, however, was not about to

3D Printing For Commercial Use | HiberXen

Yes, 3D printing can be used for commercial purposes. 3D printing has revolutionized manufacturing and prototyping, allowing businesses to create products and parts quickly and affordably. However, 3D printing is still in its early stages, and there are a few challenges that need to be

3D Printing Molds For Resin Casting | HiberXen

Yes, you can use a 3D printer to make molds for resin casting. 3D printing has become increasingly popular in recent years as a means of fabricating objects from a digital file. One of the most common applications for 3D printing is creating molds for

Difference Between Additive Manufacturing And 3D Printing

Additive manufacturing is the process of successively adding material to build an object from scratch. 3D printing is a subset of additive manufacturing that refers to the specific process of joining materials layer by layer to create an object. In additive manufacturing, objects are created

Is Additive Manufacturing The Same As 3D Printing?

Yes, additive manufacturing is the same as 3D printing. Additive Manufacturing (AM) and 3D printing are often used interchangeably, but there is a difference between the two processes. 3D printing is a subset of AM, and all 3D printing is AM, but not all AM

Is Rapid Prototyping The Same As 3d Printing?

No, rapid prototyping is not the same as 3d printing. Yes, rapid prototyping and 3D printing are the same thing. Both terms refer to the process of quickly creating a three-dimensional model of a product or object using a computer-aided design (CAD) program. This model

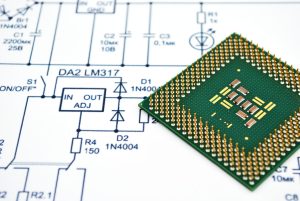

In-Depth of Printed Circuit Board Material (Etched PCB)

Many different types of materials can be used for a printed circuit board. A printed circuit board, or PCB, is one or more layers of insulating material with conductive pathways etched into it. A PCB supports mechanically and electrically connecting electronic components using conductive tracks,

Automated PCB Testing Machine | HiberXen

A machine that tests printed circuit boards for defects. An automated pcb testing machine is a device that can be used to test the functionality of printed circuit boards (PCBs). This type of machine is typically used by manufacturers to test the quality of their