Flexible PCB Design & Capabilities

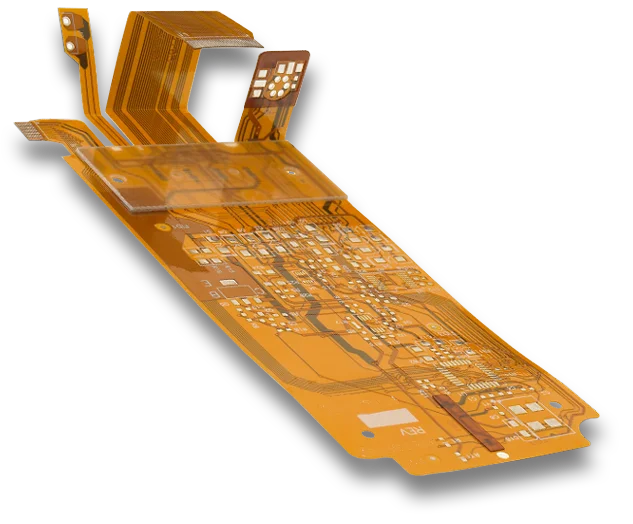

Flexible PCB

Flexible PCBs offers physical and electrical interconnect solutions that cannot be achieved with rigid PCB. Hiberxen offers a comprehensive range of Flexible PCB manufacturing and PCB assembly.

A Flexible PCB having a base material composed of polyester resin or polyimide resin. It can be variously bent and folded according to the manufacturing needs of any particular application.

The basic portion of Flexible PCB is a film, which is used to support circuits composed of copper pieces. The various flexible PCB manufacturing process properties belonging to a flexible PCB include: lite, softness, thinness, flexibility and high-wiring density.

Accordingly, the flexible PCB offers design freedom in electronic equipment and in particular, saves an amount of wasted space, thereby downsizing the equipment.

Flexible PCB Types

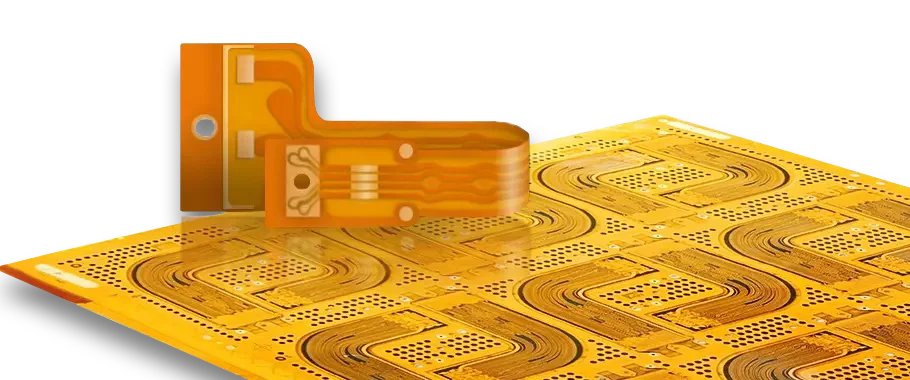

Flexible PCB applications typically include designs where the PCB wraps around other electrical subsystems against the inside of an applications enclosure. Consequently, the material options commonly available for these purposes have specific mechanical, thermal and chemical properties. It is possible to adapt this layer depending on the desired performances, mechanical strength, temperature resistance, bending. we offer rigid PCBs in a range of types, including:

- Single-layer flexible PCB:

One conductive copper layer bonded between two insulating polyimide layers

Example construction: cover-lay/copper/flex core. - Double-layer flexible PCB:

Two conductive copper layers with an insulating polyimide between and external polyimide insulating layers. Plated through-holes provide circuit connection between layers.

Example construction: Cover-lay/copper/flex core/copper/cover-lay. - Multi-layer flexible PCB:

Three or more up to 8 flexible conductive layers with flexible insulating layers between each one and external polyimide insulating layers

Plated through-holes provide circuit connection between layers.

Example construction: Cover-lay/copper/flex-core/copper/adhesive/flex-core/copper/cover-lay.

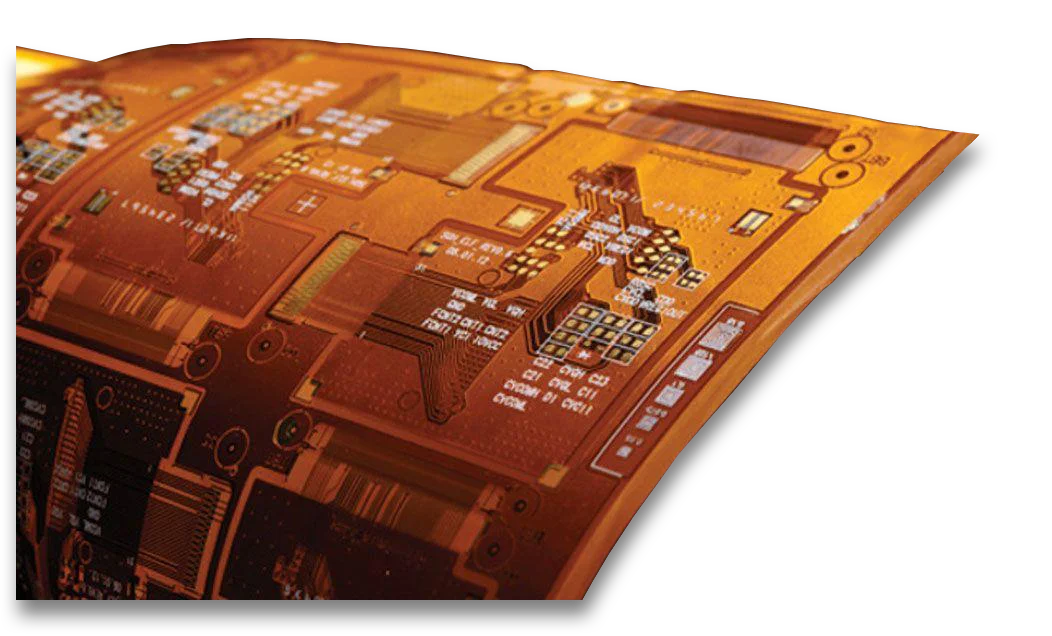

Flex Core Materials:

Standard thicknesses: 1/2 mil to 3 mil in either adhesive or adhesiveless constructions.

Standard copper thicknesses: 1/3 oz to 2 oz in rolled annealed or electro deposited formats.

Cover-lays:

Standard thickness: 1/2 mil to 2 mil polyimide, with 1/2 mil to 2 mil epoxy or acrylic adhesive

Stiffeners:

Component support or ZIF connector thickness requirements

Materials: polyimide, FR4, stainless steel, aluminum.

PSA (pressure sensitive adhesives) available for attachment purposes.

EMI/RF shielding films available.- Single-layer flexible PCB:

Flex PCB Capabilities

| Item | Description | Remark | |

| Layer | Flex board : 1 – 8 Layers | ||

| Material | PI, PET, PEN, FR-4 | ||

| Final Thickness | Flex board : 0.002″ – 0.1″ (0.05 – 2.5mm) | ||

| Surface Treatment | Lead-free : ENG Gold, OSP, Immersion silver, Immersion Tin | ||

| Max / Min Board Size | Min : 0.2″x0.3″ Max : 20.5″x13″ | ||

| Min Trace Width / Min Clearance | Inner : 0.5oz: 4/4mil 1oz: 5/5mil 2oz: 5/7mil | Outer : 1/3oz-0.5oz: 4/4mil 1oz: 5/5mil 2oz: 5/7mi | |

| Min Hole Ring | Inner : 0.5oz: 4mil 1oz: 5mil 2oz: 7mil | Outer : 1/3oz-0.5oz: 4mil 1oz: 5mil 2oz: 7mil | |

| Copper Thickness | 1 / 3oz – 2oz | ||

| Max / Min Insulation Thickness | 2mil / 0.5mil (50um / 12.7um) | ||

| Min Hole Size and Tolerance | Min hole : 8mil Tolerance : PTH±3mil, NPTH±2mil | ||

| Min Slot | 24mil x 35mil (0.6×0.9mm) | ||

| Solder Mask Alignment Tolerance | ±3mil | ||

| Silkscreen Alignment Tolerance | ±6mil | ||

| Silkscreen Line Width | 5mil | ||

| Gold Plating | Nickel : 100u” – 200u” | Gold : 1u”-4u” | |

| Immersion Nickel / Gold | Nickel : 100u” – 200u” | Gold : 1u”-5u” | |

| Immersion Silver | Silver : 6u” – 12u” | ||

| OSP | Film : 8u” – 20u” | ||

| Test Voltage | Testing Fixture : 50-300V | ||

| Profile Tolerance of Punch | Accurate mould : ±2mil | ||

| Ordinary mould : ±4mil | |||

| Knife mould : ±8mil | |||

| Hand-Cut : ±15mil | |||

We're here to help

Our team is ready for you. Feel free to contact us by e-mail or our social media, so we can learn more about you and your needs.