- +86-0755-23211352

- sales@hiberxen.com

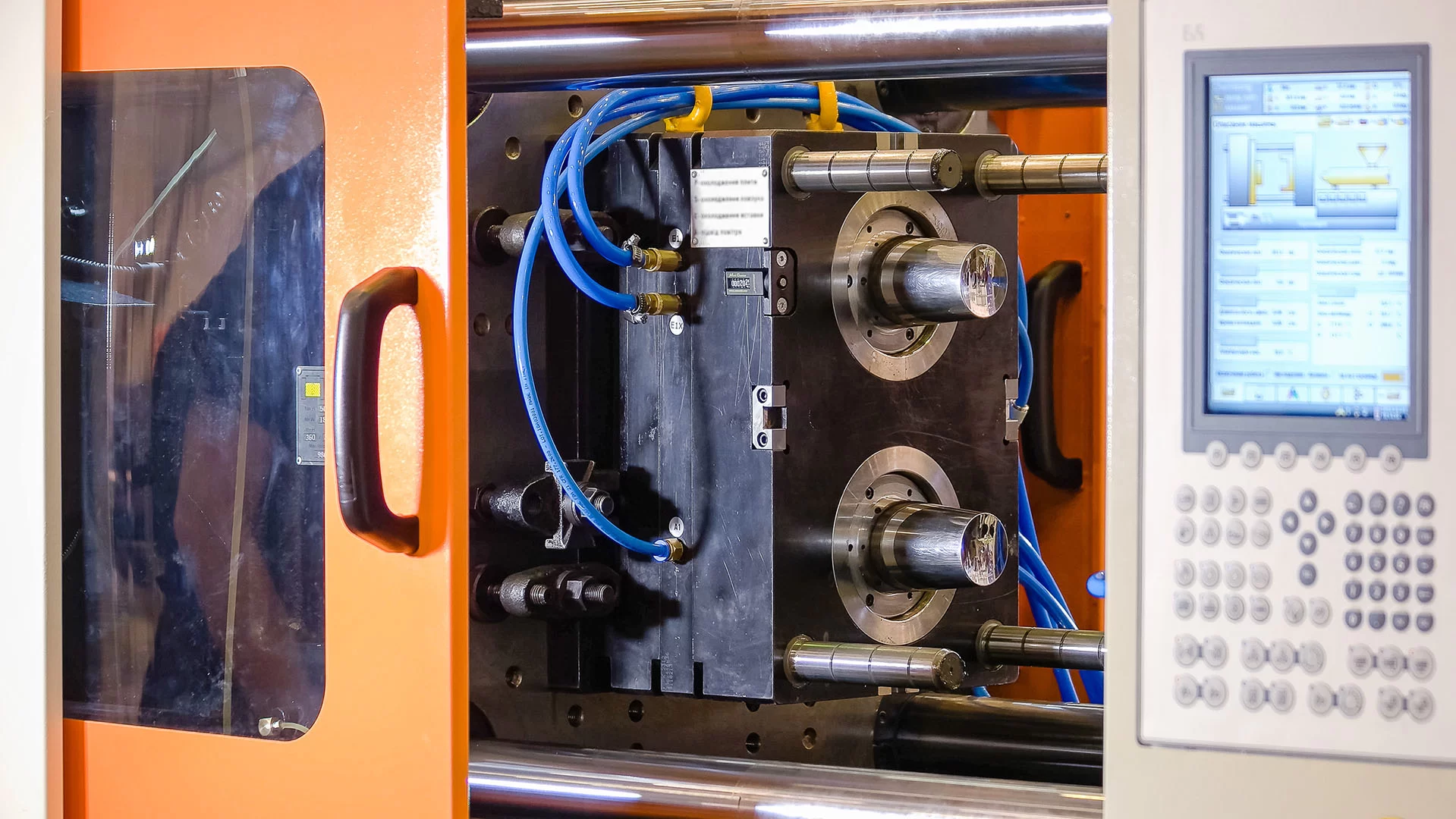

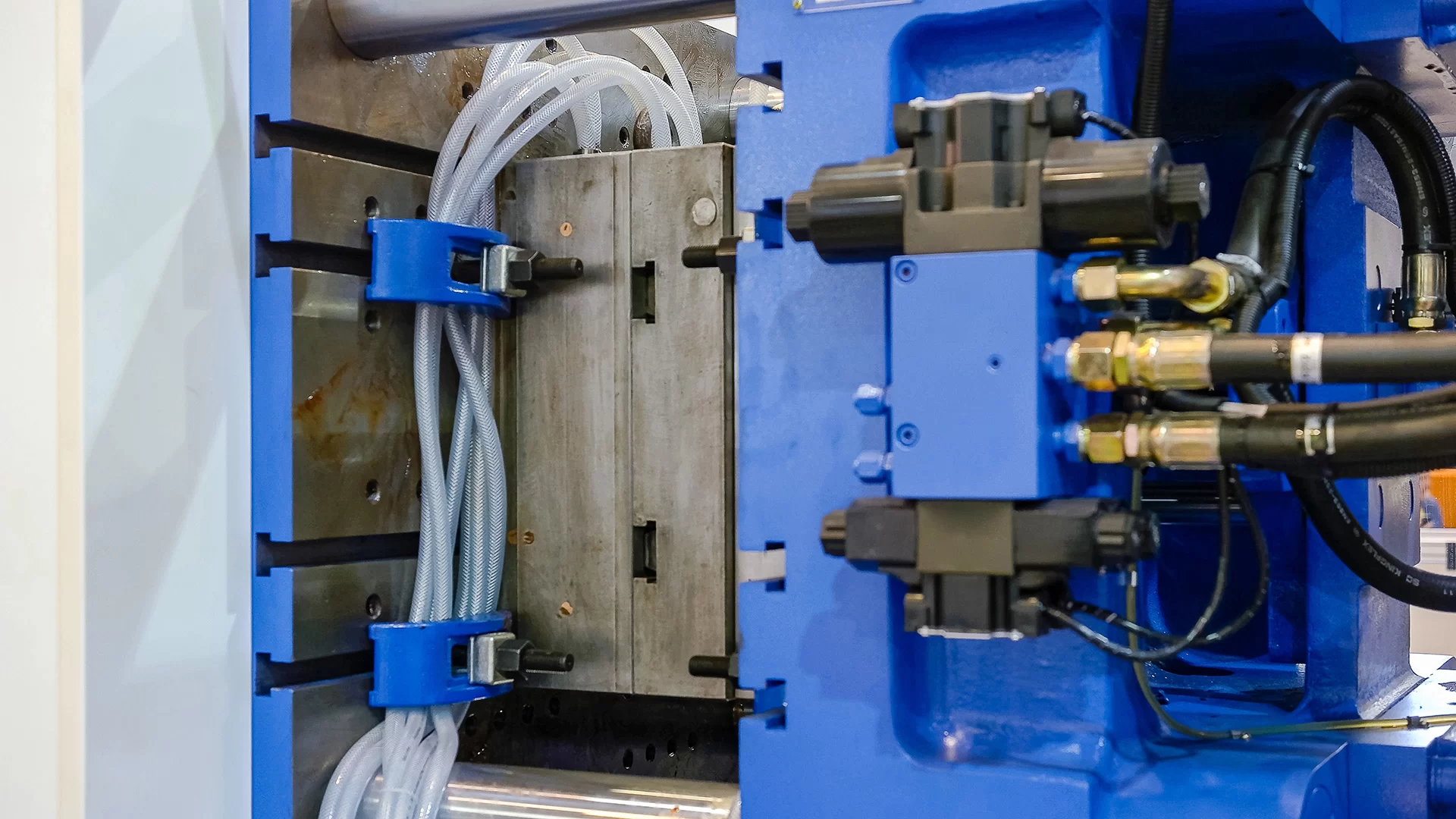

Plastic Injection Molding

Capabilities and Limitations.

Injection Molding

Injection Molding Design Services

Our plastic injection molding process produces custom – rapid prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.

Plastic Injection Molding Design Guidelines will help you understand capabilities and limitations.

We have two injection molding service options—prototyping and on-demand manufacturing—with each offering their own benefits depending on your project needs. If part quantities are higher, an affordable piece-part price is important and quick-turn production throughout the product life cycle is critical. For this our on-demand manufacturing option is ideal.

Injection Molding Design Process

In the initial stage our experienced team members work together to determine product specifications, mold component functionality, mold materials, operational constraints and any needed product enhancements and improvements. The team especially looks for any potential problems in part geometry or tolerance that might result in poor quality conditions or require special tooling features.

We can produce thousands of parts to speed up your product development cycle. You can choose from large variety of materials. For molded end products, we have many finishing options. Our injection molding capabilities are plastic molding, insert molding, over molding, and family molding.

- Tooling and Production: HiberXen’s manufactures custom plastic injection molds, plastic parts and CNC machined plastic prototypes. Our capabilities include over-molding, insert molding and family molds. We offer a variety of plastic materials, colors and surface finishes. Our proprietary mold frame exchange technology is one of the key factors why we can produce your injection molds and parts at such high speed and at such a low cost.

- Over-molding: HiberXen has over-molding processes where one thermoplastic material is molded over another material to form one part. Our over-molding capabilities typically involve soft thermoplastic materials such as urethanes and thermoplastic elastomers (TPE) being over-molded onto hard plastic such as ABS or PC, for example.

- Insert Molding: This is an injection molding process by which metal inserts such brass nuts, screws, bushings or mesh filters are combined into one part by injecting thermoplastic around them. Our insert molding capabilities can include a variety of insert materials such as metal or ceramic.

- Ultrasonic Welding: HiberXen’s ultrasonic welding process uses high frequency mechanical sound waves (ultrasonics) to create molecular heat between thermoplastic materials so the plastic will melt and form a molecular bond between the parts to join two parts together.

- Pad Printing: A printing process that can transfer a 2D image onto a 3D object.

- Silk Screening: A printing technique that uses a woven mesh to support an ink-blocking stencil to receive a desired image.

- Functional Testing by Customer Specification: HiberXen provides functional testing services required by customers. Typically testing includes leak testing, impact testing, and pressure testing.

Our Projects

Thin-Wall Molding

Liquid Silicone Injection Molding

Structural Foam Molding

Metal Injection Molding

Gas-Assisted Injection Molding

We're here to help

Our team is ready for you. Feel free to contact us by e-mail or our social media, so we can learn more about you and your needs.