There are many companies that offer reverse engineering pcb services.

When you need a printed circuit board (PCB) manufactured, you typically start with a design. This design is then sent to a PCB manufacturer who will “reverse engineer” the design and create the PCB. The process of reverse engineering a PCB design is relatively simple and does not require a lot of specialized equipment.

The first step in reverse engineering a PCB design is to obtain the design files from the customer. These files can be in a variety of formats, but the most common are Gerber files. Once the files are obtained, they are loaded into the CAM (computer-aided manufacturing) software.

The CAM software is used to generate the manufacturing data that will be used to actually create the PCB. This data includes things like the dimensions of the PCB, the location of the holes, and the width of the traces.

Once the manufacturing data is generated, it is sent to the PCB manufacturer. The manufacturer will use this data to create the PCB. The process of creating a PCB is beyond the scope of this article, but suffice it to say, it involves using a variety of machines to etch the traces onto a piece of copper clad board and then solder the components onto the board.

Once the PCB is manufactured, it is sent back to the customer for assembly. The customer will then populate the PCB with components and test it to ensure it functions as intended.

Reverse engineering PCB services is a relatively simple process

What Is Reverse Engineering Pcb Services?

Reverse engineering pcb services is the process of taking a pcb design and recreating it.

In the electronics industry, “reverse engineering pcb” refers to the process of taking an existing printed circuit board (PCB) design and extracting the underlying design data. This data can then be used to create a new PCB with the same or similar functionality. reverse engineering pcb is often performed when the original design data is no longer available, or when the PCB needs to be modified to add new features or fix bugs.

There are many reasons why you might need to reverse engineer a PCB. Maybe you have an old PCB that you want to use as a template for a new design. Or maybe you need to make changes to an existing PCB but don’t have the original design files. Whatever the reason, reverse engineering can be a valuable tool.

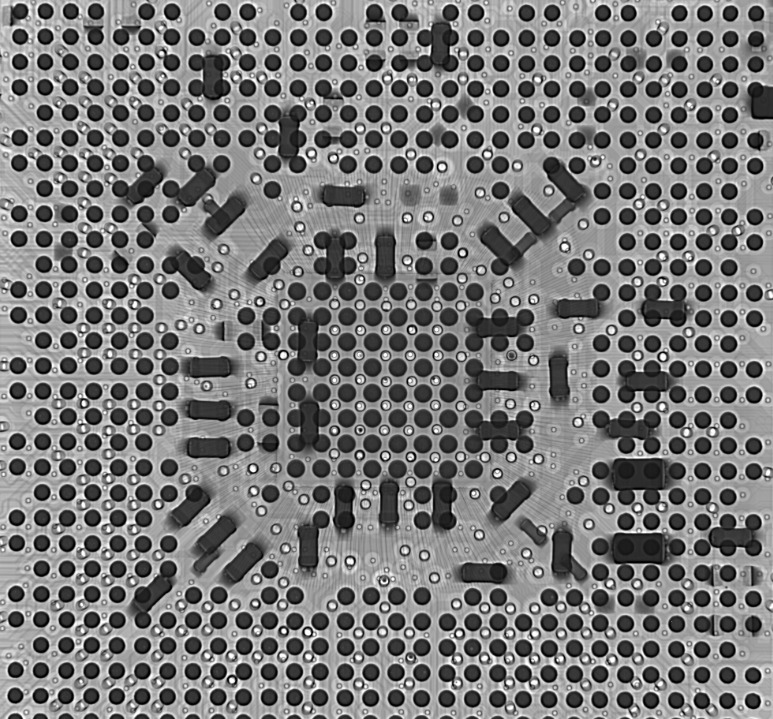

There are a few different ways to reverse engineer a PCB. The most common is to use a scanning electron microscope (SEM) to take high-resolution photos of the PCB. These photos can then be used to create a new PCB design.

Another method is to use a PCB milling machine to physically remove layers of the PCB, one at a time. This can be a time-consuming process, but it can be very accurate.

Once you have the design data, you can use it to create a new PCB with the same or similar functionality as the original. You can also use the data to make modifications to the design, such as adding new features or fixing bugs.

Reverse engineering can be a valuable tool for anyone who works with PCBs. Whether you’re trying to create a new design or modify an existing one, reverse engineering can help you get the job done.

What Are The Benefits Of Reverse Engineering Pcb Services?

Reverse engineering pcb services allow you to find any errors or issues in your design, and correct them before manufacturing.

Reverse engineering is a process where a product is deconstructed to reveal its design, functionality, and manufacturing processes. In the case of printed circuit board (PCB) services, reverse engineering can be used to improve upon an existing design, create a compatible replacement for a discontinued board, or to simply understand how a particular board works.

There are many benefits to reverse engineering PCB services, such as:

1. Increased flexibility: When you have the ability to deconstruct and examine a product, you can more easily make changes or improvements to the design. This is especially helpful when you need to make a compatible replacement for a discontinued board.

2. Improved understanding: By understanding how a particular board works, you can be better equipped to troubleshoot problems or make modifications as needed. This can save time and money in the long run.

3. Cost savings: In some cases, reverse engineering can be less expensive than starting from scratch. This is especially true when you need to make a compatible replacement for a discontinued board.

4. Faster time to market: When you can use reverse engineering to improve upon an existing design, you can get your product to market faster than if you were starting from scratch.

5. Greater innovation: By understanding how a product works, you can more easily come up with new ways to improve upon it. This can lead to greater innovation and a competitive edge for your business.

Overall, reverse engineering PCB services can offer many benefits, from increased flexibility and understanding to cost savings and a faster time to market. If you are considering reverse engineering for your business, be sure to weigh the pros and cons to decide if it is the right solution for you.

What Are The Challenges Involved In Reverse Engineering Pcb Services?

The main challenge involved in reverse engineering pcb services is figuring out how the original design was created and then recreating it.

Reverse engineering PCB services can be a challenge, especially if you’re not familiar with the process. Here’s a quick rundown of the steps involved:

1. Obtain the schematics and board layout files for the PCB. This can be done by requesting them from the manufacturer, or by reverse engineering the PCB itself.

2. Create a netlist of the PCB. This is a list of all the components and their connections.

3. Create a bill of materials (BOM) for the PCB. This is a list of all the components and their corresponding values.

4. Verify the accuracy of the netlist and BOM. This can be done by comparing them to the manufacturer’s data, or by simulating the PCB.

5. Order the necessary components and assemble the PCB.

6. Test the PCB to ensure it functions as intended.

Reverse engineering PCB services can be time-consuming and expensive, but it’s often necessary in order to create a compatible replacement or upgrade for an existing PCB.

How Can Reverse Engineering Pcb Services Be Used To Improve Product Development?

Reverse engineering pcb services can be used to improve product development by allowing engineers to analyze and improve upon the design of existing products.

Reverse engineering is the process of taking a product apart and reconstructing it in order to better understand how it works. This can be done for a variety of reasons, such as to improve upon the original design or to create a knock-off product.

Reverse engineering PCB services can be used to improve product development in a number of ways. For example, if you are trying to create a new product that is similar to an existing one, you can use reverse engineering to figure out how the existing product works and what design changes you need to make to improve upon it.

There are a number of companies that offer reverse engineering services, so if you are interested in using this technique to improve your product development process, you should do some research to find a reputable provider. Once you have found a provider, you can send them your product and they will take it apart and send you back a report explaining how it works.

One example of a company that offers reverse engineering services is PCBCart. They are a leading provider of PCB manufacturing and assembly services. If you send them your product, they will take it apart and send you back a report that includes a schematic of the product, a BOM (bill of materials), and a detailed analysis of the design.

This type of service can be very helpful if you are trying to create a new product or improve upon an existing one. By understanding how the existing product works, you can make the necessary changes to create a better version.

How Can Reverse Engineering Pcb Services Be Used To Improve Manufacturing Processes?

Reverse engineering pcb services can be used to improve manufacturing processes by allowing manufacturers to see how their products are made and identify areas where improvements can be made.

Reverse engineering is the process of taking a product apart and analyzing its components and design. This can be done for a variety of reasons, such as to improve upon the design or to find out how the product was made so that it can be replicated.

In the world of electronics, reverse engineering PCB services can be used to improve manufacturing processes. By taking apart a PCB and analyzing its design, engineers can find ways to improve the manufacturing process and make it more efficient. This can lead to savings in time and money for the company.

One example of how reverse engineering PCB services can be used to improve manufacturing processes is the case of the iPhone 6. In 2014, Apple released the iPhone 6, which was widely considered to be one of the best smartphones on the market. However, there were some reports of the phone bending easily.

Apple responded to this by asking its manufacturing partner, Foxconn, to investigate the issue. Foxconn reverse engineered the iPhone 6 and found that the issue was caused by a design flaw. They were then able to redesign the manufacturing process to fix the issue and prevent it from happening in future products.

This is just one example of how reverse engineering can be used to improve manufacturing processes. In today’s ever-changing world, companies are always looking for ways to improve their products and manufacturing processes. By reverse engineering their products, they can find ways to make them better and more efficient.

FAQ

What Are The Limitations Of Reverse Engineering Pcb Services?

How Much Does Reverse Engineering Pcb Services Cost?

Are There Any Risks Associated With Reverse Engineering Pcb Services?

If you still have any questions after reading this, feel free to leave a comment below.

Author

-

I'm Shahrear, a Designer Lead who loves electronics. Since 2003, I’ve been traveling and living all over the world. I love breaking down complex concepts in electronics and presenting them to others in an approachable way. I think that the language used in most books about electronics is hard for people who don't already know about electronics to understand. I want that to change. So, I've started blog where I talk about everything on electronics for people who are just starting out.

View all posts