Rigid PCB Design & Capabilities

Rigid PCB

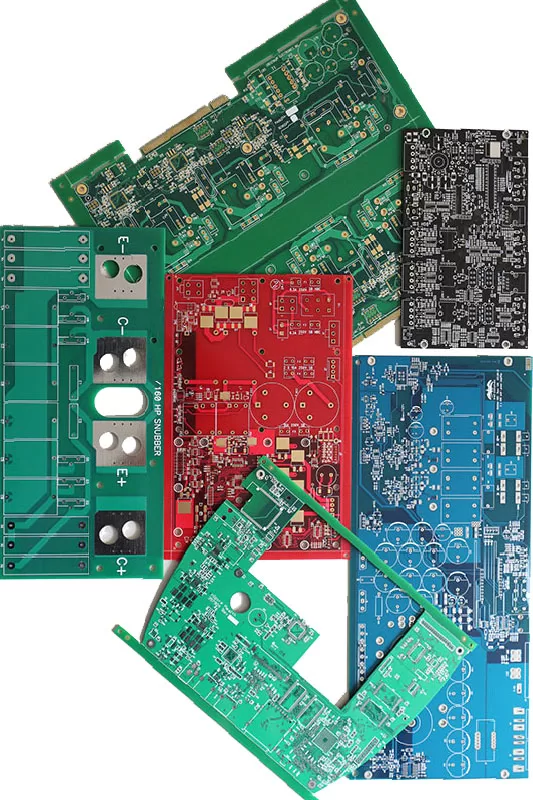

Hiberxen produces rigid PCBs according to your exact project specifications. With a range of capabilities, materials and configurations, your rigid PCB can operate in many environments with reliable durability.

Our rigid PCB solutions make it possible to create a cost-effective PCB that can operate in harsh conditions. As the true standard for circuit boards, rigid PCBs maintain their shape and prevent distortion in various applications.

A rigid PCB is naturally versatile and works in various configurations from single-layer to multilayer. With our design for manufacturability and engineering services, you can find a rigid PCB that complements your size, material and build specifications.

RIGID PCB TYPES

The advantages of Rigid PCBs are their ability to work well for various project specifications and configurations. we offer rigid PCBs in a range of types, including:

- Single-layer: Single-layer PCBs have only one layer of conductive material, and all components are located on one side of PCB. Single-layer PCBs are fast and easy to manufacture, reduces the possibility of mistakes and cost-effective configuration thrives in low-density designs.

- Double-layers: Rather than single conductive layer, double-sided PCBs utilize copper conductive layers on both sides. With twice the space for components, double-layer PCBs have more design options and increased circuit complexity, making them applicable for a wide range of projects.

- Multi-layer: This type of PCB uses three or more layers of conductive material stacked in the middle with several other layers surrounding the core. With numerous layers and an advanced curing process, multilayer boards reduce the need for interconnection wiring, save space and result in a dense and tough PCB. We can design multi-layer PCBs up to 32 layers with any shape and complexity.

Rigid PCB Capabilities

| Item | Description | Remark | |

| Layer | 1- 32 Layers (FR- 4, FR- 406, 370 HR) 1- 2Layers (Rogers, Aluminum, Copper, Steel, Ceramic Base, TEFLON) | ||

| Material | FR- 4, FR- 406, 370 HR; Rogers4003; Rogers4350 Aluminum, Copper, Steel, Ceramic Base, TEFLON | ||

| Finish Thickness | Finish Thickness: 0.008″ – 0.275″ (0.2mm- 7mm) | ||

| Min Thickness | 2- layer: 0.008″ (0.2mm) 4- layer: 0.016″ (0.4mm) 6- layer: 0.024″ (0.6mm) 8- layer: 0.032″ (0.8mm) 10- layer: 0.04″ (1mm) More than 10layers (0.5Xnumber of layers X0.008″) | ||

| Surface Finishing | Lead Finishing: HASL, HASL + Gold finger Lead- free Finishing: Lead- free HASL, ENG Gold; OSP, Immersion Silver | ||

| Special Process | Impedance board (request as±10%) High TG / Halogen- free/ Halogen- free & High TG board | ||

| Min Trace Width / Min Clearance | Inner Layers (trace width/clearance) 0.5oz: 2.5/ 2.5mil 1oz: 3/ 3mil 2oz: 5/ 7mil 3oz: 7/ 8mil 4oz: 10/ 10mil 5oz: 12/ 12mil 6oz: 15/ 12mil | Outer Layers (trace width/clearance) 1/ 3oz- Haz: 3/ 3mil 1oz: 3.5/ 3.5mil 2oz: 5/ 7mil 3oz: 7/ 8mil 4oz: 10/ 10mil 5oz: 12/ 12mil 6oz: 15/ 12mil | |

| Aspect Ratio | Min Hole Size 6mil | ||

| Min Hole Ring | Inner: 0.5oz: 4mil 1oz: 5mil 2oz: 6mil 3oz: 9mil 4oz: 12mil 5oz: 15mil 6oz: 17mil | Outer: 1/ 3oz -0.5oz: 4mil 1oz: 4mil 2oz: 6mil 3oz: 9mil 4oz: 12mil 5oz: 15mil 6oz: 17mil | |

| Copper Thickness | Inner: H0.5oz, 1oz, 2oz, 3oz, 4oz, 5oz. 6oz Outer: 1/ 3oz, 0.5oz, 1oz, 2oz, 3oz, 4oz, 5oz, 6oz | ||

| Min Hole Size and Tolerance | Min Finish Hole: 6mil Hole Tolerance: ±3mil | ||

| Thickness of Plating Layer | · HASL: Copper Thickness: 20um -35um Tin 5 -20um · Immersion Gold: Nickel 100u” -200 u” Gold 2u” -4u” · Hard Plated Gold: Nickel 100u” -200 u” Gold 4u” -8u” · Golden Finger: Nickel : 100u” -200 u” Gold : 5u” -15u” · Immersion Silver: 6u” -12u” · OSP: Film 8u” -20u” | ||

| Solder Mask Color | Glossy : Green, Black, Red, Yellow, White, Purple, Blue Matt : Green, Black | ||

| Solder Mask Resolution | Solder Mask Thickness : 0.2mil -1.6mil Solder Dam : Green 7mil /Other Color 8mil Solder Mask Hole Plug Diameter : 10mil -25mil | ||

| Silk Screen Color | White, Black | ||

| Profile | Punch Tol: ±5mil CNC Tol: ±5mil V- CUT Tol: ±10mil Bevel Edge: ±5mil Slot Min: 32mil Angel: 15°, 20°, 30°, 45°, 60° | ||

| Bow and Twist | SMT≤0.75% None SMT≤1% | ||

| Accept Standard | IPC Class 2; IPC Class 3; ISO9000 | ||

We're here to help

Our team is ready for you. Feel free to contact us by e-mail or our social media, so we can learn more about you and your needs.