A SMT line is a line of machines that produces surface-mount technology devices.

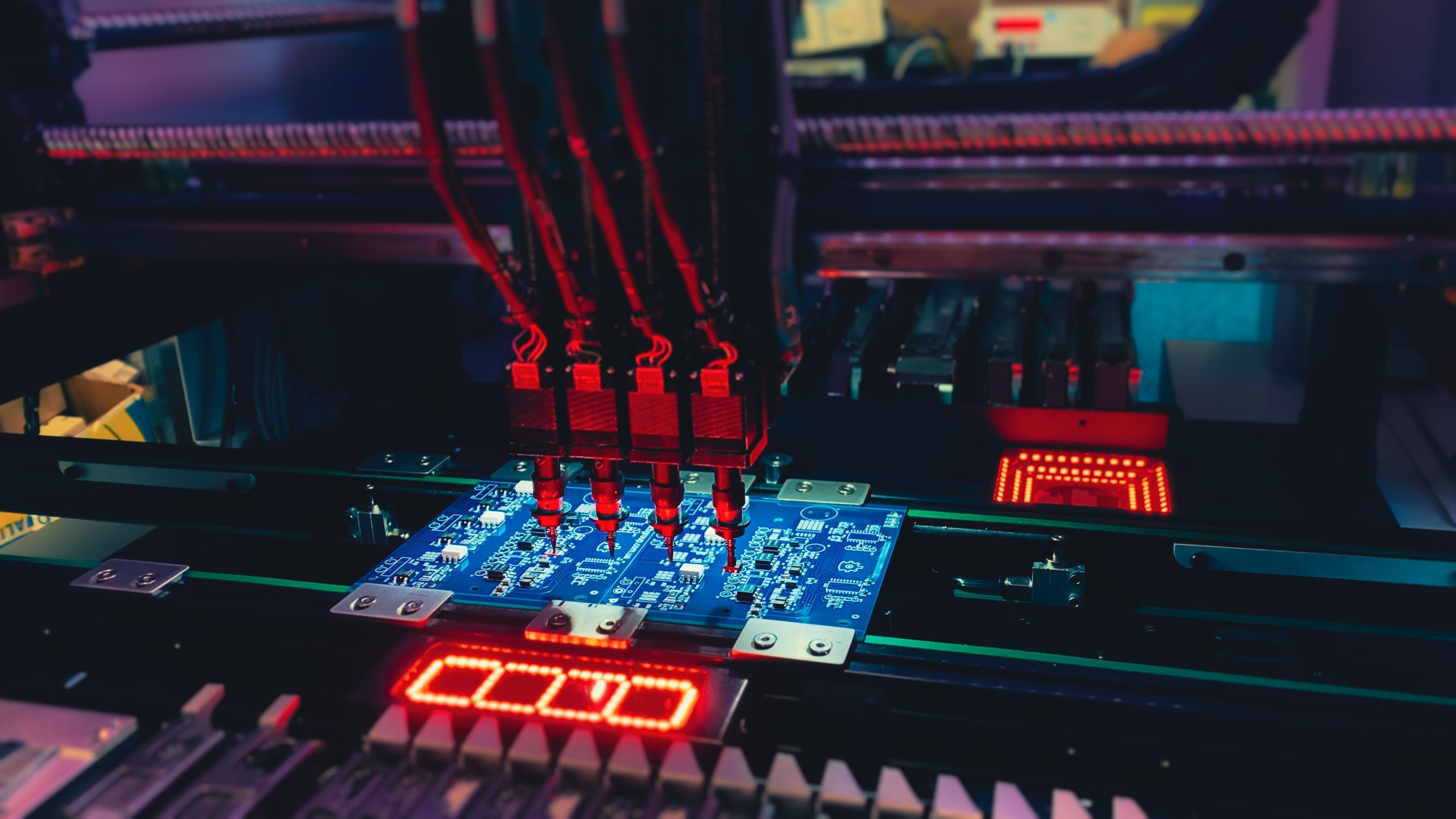

An SMT line is a type of production line that is used to assemble Surface Mount Technology (SMT) components onto printed circuit boards (PCBs). The SMT line typically consists of a series of conveyors, each of which is equipped with a different type of machine that performs a specific task in the assembly process.

The first step in an SMT line is to load the PCBs onto the conveyor. The PCBs are then conveyed to a pick-and-place machine, which picks up the SMT components from a feeder and places them onto the PCB. After the components are placed, the PCBs are conveyed to an oven, where the components are soldered onto the PCB. Finally, the PCBs are conveyed to a final inspection station, where they are checked for quality.

SMT lines can be highly automated, with all of the machines in the line being controlled by a central computer. This allows for a high degree of accuracy and consistency in the assembly process.

What Is An SMT Line?

An SMT line is an automated production line for printed circuit boards.

An SMT line is a production line for mounting surface-mount technology (SMT) components onto a printed circuit board (PCB). The SMT line typically consists of four main sections: a board in-feed section, a component placement section, a soldering section, and a board out-feed section.

The board in-feed section is where the PCBs are fed into the production line. The component placement section is where SMT components are placed onto the PCBs. The soldering section is where the SMT components are soldered onto the PCBs. The board out-feed section is where the PCBs are discharged from the production line.

A typical SMT line can handle up to 2000 PCBs per hour. The SMT line can be fully automated, semi-automated, or manual.

A real-life example of an SMT line is the production line at a factory that manufactures electronic devices.

What Are The Benefits Of An SMT Line?

There are many benefits to an SMT line, including increased production speed, decreased production costs, and improved product quality.

An SMT line is a production line used for surface-mount technology, where electronic components are mounted onto the surface of a PCB. The main benefits of using an SMT line are:

1. Increased production efficiency: SMT lines are designed for high-volume production, and can therefore churn out PCBs at a much faster rate than manual assembly.

2. Reduced production costs: The automated nature of SMT lines also reduces the overall cost of production, as fewer labor hours are required.

3. Improved product quality: With SMT lines, there is less scope for human error, resulting in a higher quality final product.

4. Increased flexibility: SMT lines can be easily reconfigured to accommodate different PCB designs and component sizes.

5. Reliable and consistent output: SMT lines provide a consistent and reliable output, which is crucial in meeting tight production deadlines.

One real-life example of a company that has benefited from using an SMT line is Apple. The Cupertino giant has used SMT lines in its factories for many years, and this has helped them to become the world’s largest technology company.

What Are The Different Types Of SMT Lines?

There are many types of SMT lines, each with different capabilities and features.

Different types of SMT lines

The term SMT line generally refers to a production line for the surface-mount technology (SMT) assembly of printed circuit boards (PCBs).

However, there are different types of SMT lines, each with its own advantages and disadvantages.

The most common type of SMT line is the batch line, where each PCB is processed one at a time.

This type of line is generally less expensive to set up and operate than other types of SMT lines, but it is less flexible and efficient.

Another type of SMT line is the continuous flow line, where multiple PCBs are processed simultaneously.

This type of line is more expensive to set up and operate, but it is more flexible and efficient.

A third type of SMT line is the mixed mode line, which combines the features of batch and continuous flow lines.

This type of line is the most expensive to set up and operate, but it is the most flexible and efficient.

Real-life example

A real-life example of an SMT line is the production line at a factory that produces cell phones.

The SMT line at this factory is a continuous flow line, where multiple PCBs are processed simultaneously.

This type of line is more expensive to set up and operate, but it is more flexible and efficient.

How Does An SMT Line Work?

An SMT line works by placing and soldering components onto a PCB.

An SMT line is a production line where surface-mount technology (SMT) components are assembled onto printed circuit boards (PCBs). The SMT line typically consists of several workstations, each of which performs a specific task in the assembly process.

The first station on the line is the component preparation station, where the SMT components are prepared for assembly. This includes loading the SMT components onto the line, separating the different types of components, and testing the components for defects.

The next station is the component placement station, where the SMT components are placed onto the PCB. This is typically done by a machine called a pick-and-place machine, which picks up the components and places them in the correct locations on the PCB.

After the component placement station, the PCB goes through an inspection station, where it is checked for defects. If any defects are found, the PCB is repaired at the next station, the repair station.

The final station on the line is the packaging station, where the PCB is packaged for shipment. This includes adding any necessary labels and packaging the PCB in an antistatic bag.

The SMT line is a production line where surface-mount technology (SMT) components are assembled onto printed circuit boards (PCBs). The SMT line typically consists of several workstations, each of which performs a specific task in the assembly process.

The first station on the line is the component preparation station, where the SMT components are prepared for assembly. This includes loading the SMT components onto the line, separating the different types of components, and testing the components for defects.

The next station is the component placement station, where the SMT components are placed onto the PCB. This is typically done by a machine called a pick-and-place machine, which picks up the components and places them in the correct locations on the PCB.

After the component placement station, the PCB goes through an inspection station, where it is checked for defects. If any defects are found, the PCB is repaired at the next station, the repair station.

The final station on the line is the packaging station, where the PCB is packaged for shipment. This includes adding any necessary labels and packaging the PCB in an antistatic bag.

How Much Does An SMT Line Cost?

The cost of an SMT line can range from $500,000 to $5 million.

If you’re considering starting up a electronics manufacturing business, you’re probably wondering how much an SMT line costs. An SMT line is a production line used for surface-mount technology, where electronic components are mounted onto the surface of a printed circuit board.

The cost of an SMT line will vary depending on the type and size of the components you’ll be using, as well as the speed and capacity of the line. A basic SMT line for small components may start around $100,000, while a high-speed line capable of handling large components could cost upwards of $1 million.

To get a better idea of what an SMT line would cost for your specific needs, it’s best to consult with a professional who can help you assess your requirements and find the right solution for your budget.

FAQ

How Long Does It Take To Set Up An SMT Line?

How Much Training Is Required To Operate An SMT Line?

What Are The Safety Precautions For Working With An SMT Line?

1. Always wear the proper personal protective equipment (PPE), including gloves, goggles, and a dust mask.

2. Be aware of potential hazards, such as chemicals, fumes, and electrical hazards.

3. Follow all safety procedures and protocols.

4. Keep the work area clean and free of clutter.

5. Report any safety concerns to a supervisor.

If you still have any questions about SMT lines, please feel free to ask them in the comments section below.

Author

-

I'm Shahrear, a Designer Lead who loves electronics. Since 2003, I’ve been traveling and living all over the world. I love breaking down complex concepts in electronics and presenting them to others in an approachable way. I think that the language used in most books about electronics is hard for people who don't already know about electronics to understand. I want that to change. So, I've started blog where I talk about everything on electronics for people who are just starting out.

View all posts