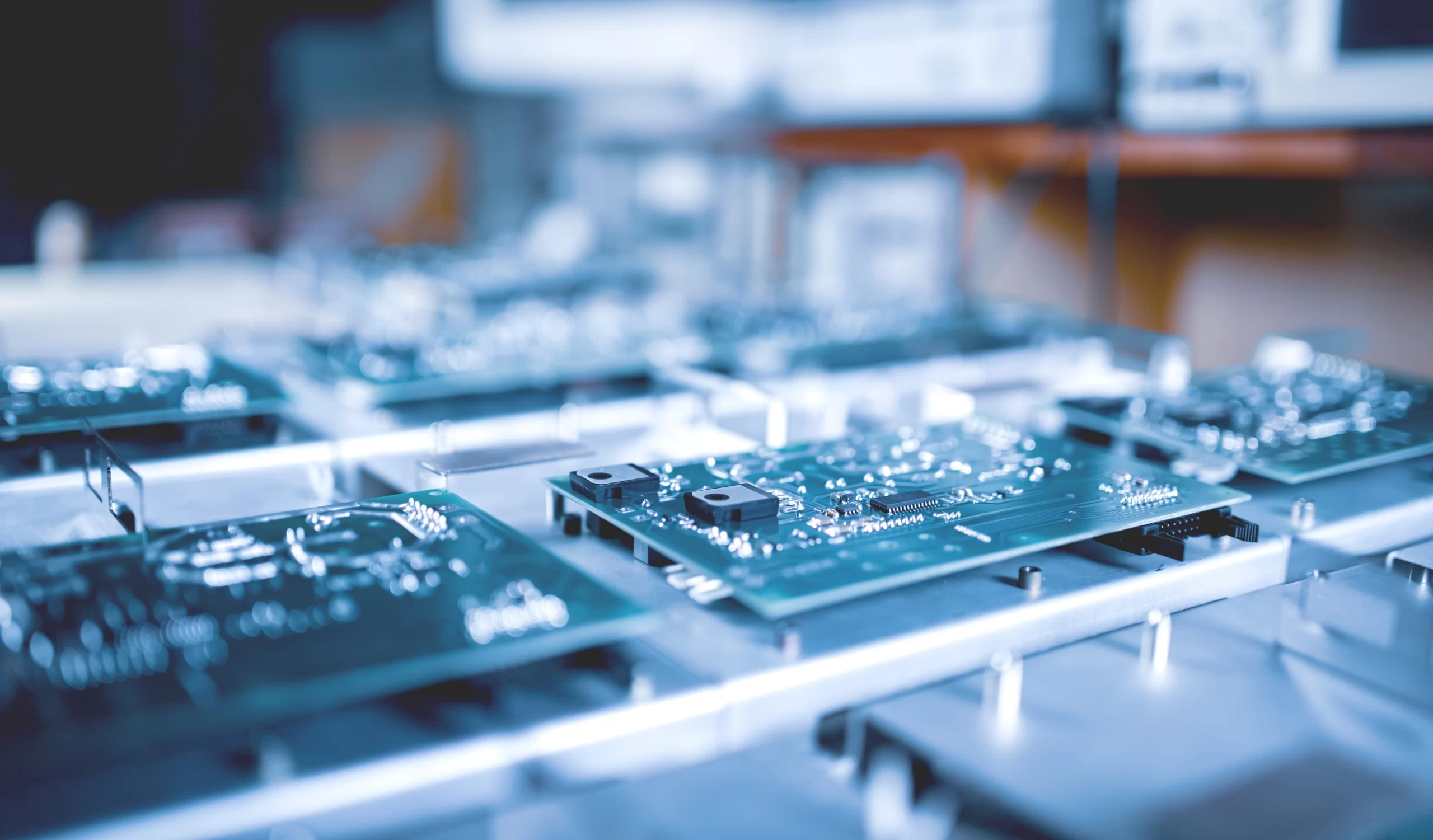

A SMT production line is a line where surface-mount technology is used to produce electronic circuit boards.

An SMT production line is a line of machines and equipment used to produce electronic circuit boards. The line typically includes machines for pick and place assembly, soldering, and inspection.

An SMT production line typically starts with a machine that places the components onto the circuit board. This machine is called a pick and place machine. The pick and place machine places the components onto the circuit board according to a design file.

After the pick and place machine, the circuit board goes through a soldering machine. The soldering machine melts solder onto the component leads and circuit board pads. This creates the electrical connection between the component and the circuit board.

After the soldering machine, the circuit board goes through an inspection machine. The inspection machine checks the circuit board for errors. The most common error is a component that is not soldered onto the circuit board.

The SMT production line is a high speed, high precision line of machines. The machines are controlled by computers and can place and solder thousands of components per hour.

What Is SMT Production Line?

A SMT Production Line is a line of machines that are used to produce Surface Mount Technology products.

An SMT Production Line is a line of machines that are used in the production of surface mount technology (SMT) products. The machines in an SMT line are used to assemble electronic components onto printed circuit boards (PCBs).

SMT lines are used in the production of a wide variety of electronic products, including cell phones, computers, and televisions. SMT lines can be custom-designed for the specific needs of a particular manufacturing process.

In general, an SMT line includes the following machines:

1. A pick-and-place machine that places electronic components onto PCBs

2. A soldering machine that solders the components to the PCBs

3. An inspection machine that checks the quality of the soldered joints

4. A packaging machine that packages the finished PCBs

5. A test machine that tests the functionality of the finished PCBs

The pick-and-place machine is the heart of an SMT line. This machine picks up electronic components from a feeder and places them onto the PCB. The pick-and-place machine is controlled by a computer, which determines the placement of the components.

The soldering machine solders the components to the PCB. The soldering machine is controlled by a computer, which determines the soldering process.

The inspection machine checks the quality of the soldered joints. The inspection machine is controlled by a computer, which determines the inspection process.

The packaging machine packages the finished PCBs. The packaging machine is controlled by a computer, which determines the packaging process.

The test machine tests the functionality of the finished PCBs. The test machine is controlled by a computer, which determines the test process.

What Is An SMT Production Line?

An SMT Production Line is a conveyor system that moves printed circuit boards (PCBs) through a series of production stages.

An SMT production line is a line of machines used to assemble Surface Mount Technology (SMT) components onto printed circuit boards (PCBs). The machines on an SMT production line include a pick-and-place machine, an inspection machine, and a reflow oven.

SMT components are small, lightweight components that are placed on the surface of a PCB. SMT production lines are used to assemble these components onto PCBs. The machines on an SMT production line work together to pick up the SMT components from their feeders, place them onto the PCB, inspect them, and reflow them.

The pick-and-place machine is the first machine on an SMT production line. The pick-and-place machine picks up the SMT components from their feeders and places them onto the PCB. The pick-and-place machine is followed by an inspection machine. The inspection machine inspects the SMT components to ensure that they are placed correctly on the PCB. The inspection machine is followed by a reflow oven. The reflow oven reflows the SMT components, which melts the solder on the SMT components and attach them to the PCB.

What Are The Benefits Of An SMT Production Line?

SMT Production Line offers many benefits such as increased productivity, flexibility, lower costs, and higher quality.

An SMT production line provides many benefits for a business, including increased efficiency and productivity, as well as improved quality control.

An SMT production line is a type of manufacturing process that involves the placement of surface-mount devices (SMDs) onto a printed circuit board (PCB). This process is typically carried out by a machine called a pick-and-place machine.

The main benefits of using an SMT production line are:

1. Increased Efficiency

An SMT production line can increase the efficiency of your manufacturing process as it is able to place SMDs onto a PCB much faster than if they were placed by hand. This can help to increase your overall production output.

2. Improved Quality Control

An SMT production line can also help improve the quality control of your manufacturing process. This is because the machine is able to place the SMDs onto the PCB with a high degree of accuracy. This can help to reduce the number of defects in your final product.

3. Reduced Costs

An SMT production line can also help to reduce the costs associated with your manufacturing process. This is because the machine is able to place the SMDs onto the PCB with a high degree of accuracy. This can help to reduce the number of defects in your final product.

4. Increased Flexibility

An SMT production line can also provide you with increased flexibility in your manufacturing process. This is because the machine is able to place the SMDs onto the PCB with a high degree of accuracy. This can help to reduce the number of defects in your final product.

What Are Some Of The Features Of An SMT Production Line?

An SMT Production Line typically consists of a Conveyor, In Feeders, an SMT Placement Machine, a Solder Reflow Oven, and a Conveyor.

If you’re looking to get into the world of electronics manufacturing, you’ll need to know about SMT production lines. Here’s a quick rundown of what they are and some of their key features.

An SMT production line is a type of manufacturing line used for making electronic circuit boards. The abbreviation SMT stands for surface-mount technology. This refers to the process of mounting electronic components onto the surface of a circuit board, as opposed to through-hole technology, which involves mounting components into holes drilled into the board.

One of the key features of an SMT production line is that it is highly automated. This means that a lot of the work is done by machines, rather than by human workers. This helps to keep costs down and to increase efficiency.

Another feature of an SMT production line is that it is flexible. This means that it can be easily reconfigured to accommodate changes in the manufacturing process. For example, if a new type of component needs to be used, the production line can be quickly adapted to accommodate it.

A third feature of an SMT production line is that it is scalable. This means that it can be easily expanded or contracted to meet changing demand. For example, if demand for a particular product increases, the production line can be quickly scaled up to meet the new demand.

SMT production lines are used in a wide variety of industries, including the automotive, aerospace, and consumer electronics industries. They are also used in the production of medical devices and in the fabrication of solar panels.

If you’re thinking of setting up your own SMT production line, there are a few things you need to keep in mind. First, you need to have a clear understanding of your manufacturing process. Second, you need to have a good understanding of the types of components you’ll be using. And third, you need to have a clear understanding of the economics of SMT production.

How Does An SMT Production Line Work?

A production line for surface-mount technology (SMT) assembly uses a conveyor to move circuit boards through each stage of the process, from start to finish.

An SMT production line is a line of machines that are used to assemble printed circuit boards. The line typically starts with a pick and place machine that places the components on the board. The components are then soldered onto the board using a reflow oven.

A typical SMT production line would have the following machines:

Pick and place machine – This machine places the components on the board.

Reflow oven – This machine solders the components onto the board.

Inspection machine – This machine inspects the boards for defects.

The production line is typically controlled by a computer that tells the machines what to do and when to do it. The computer also keeps track of the boards as they move through the line.

A real-life example of an SMT production line would be a line in a factory that makes printed circuit boards for computers.

FAQ

How Can An SMT Production Line Improve Efficiency?

What Are The Disadvantages Of An SMT Production Line?

How Much Does An SMT Production Line Cost?

Is An SMT Production Line Right For My Business?

An SMT production line is a type of production line that is typically used in the electronics industry. In an SMT production line, electronic components are placed on a circuit board by a machine called a pick-and-place machine. The components are then soldered onto the circuit board by a machine called a solder paste printer.

An SMT production line can be a good option for a business that manufactures electronic products. The SMT production line can help to improve the efficiency of the manufacturing process and can also help to reduce the cost of production.

Does this answer your question? If not, please let us know what we can clarify.

Author

-

I'm Shahrear, a Designer Lead who loves electronics. Since 2003, I’ve been traveling and living all over the world. I love breaking down complex concepts in electronics and presenting them to others in an approachable way. I think that the language used in most books about electronics is hard for people who don't already know about electronics to understand. I want that to change. So, I've started blog where I talk about everything on electronics for people who are just starting out.

View all posts